Pinhole Detection Utilizing UHR Axial MFL and Caliper ILI

ENTEGRA to present at various conferences worldwide on pinhole detection using our very own UHR MFL/CAL combination ILI technology. Abstract: With the advent of ENTEGRA’s UHR MFL/Caliper combination tools, the detection, characterization, and sizing of true pinhole anomalies is a new frontier for ILI and pipeline integrity. The paradigms to be challenged are that axial …

ENTEGRA to present at various conferences worldwide on pinhole detection using our very own UHR MFL/CAL combination ILI technology.

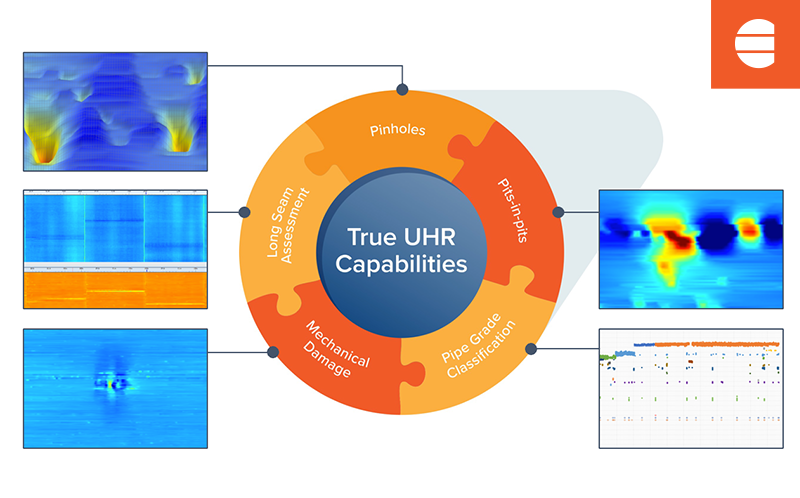

Abstract: With the advent of ENTEGRA’s UHR MFL/Caliper combination tools, the detection, characterization, and sizing of true pinhole anomalies is a new frontier for ILI and pipeline integrity. The paradigms to be challenged are that axial MFL isn’t capable of sufficient detection/accuracy for pinholes, UT is more accurate than MFL, and in-the-ditch NDE techniques are more trustworthy than MFL In-line inspection results.

This paper will discuss the advantages of utilizing UHR MFL/Caliper in-line inspection technologies to detect, characterize, and size pinhole anomalies. Pull testing on manufactured defects demonstrated that 3mm (1/8th inch) defects could be reliably detected, characterized, and sized down to depths of 10% internally and 20% externally. Field correlation of internal and external pinhole corrosion features validated the sizing specifications and exposed the real-world challenges in-the ditch NDE techniques experience locating the pits and capturing the true depth. Further laboratory testing compared the effectiveness of various in-the-ditch NDE techniques and identified some recommended best practices.