Corrosion Or Puddle-Weld? A Closer Look.

It can be difficult for traditional MFL techniques to differentiate between numerous puddle welds and actual metal loss in reconditioned pipe. Other MFL systems are known to generate an unacceptable number of false calls. The edge effects of the metal deposition can cause false positives, resulting in unnecessary digs. Puddle weld interactions with actual metal loss can also cause false negatives (again, for other MFL systems), masking potentially injurious metal loss. If you’ve inspected puddle welded pipe …

It can be difficult for traditional MFL techniques to differentiate between numerous puddle welds and actual metal loss in reconditioned pipe. Other MFL systems are known to generate an unacceptable number of false calls. The edge effects of the metal deposition can cause false positives, resulting in unnecessary digs. Puddle weld interactions with actual metal loss can also cause false negatives (again, for other MFL systems), masking potentially injurious metal loss. If you’ve inspected puddle welded pipe before, then you’ve experienced the frustrations that we’re talking about.

Correct characterization is tedious and time consuming even for an experienced hands-on analyst, so it’s not surprising that it’s almost impossible for automated searches to make sense of these very critical calls. Eliminating false calls with puddle welded pipe is the name of the game, and one best accomplished by experienced data analysts who have “been there and done that.”

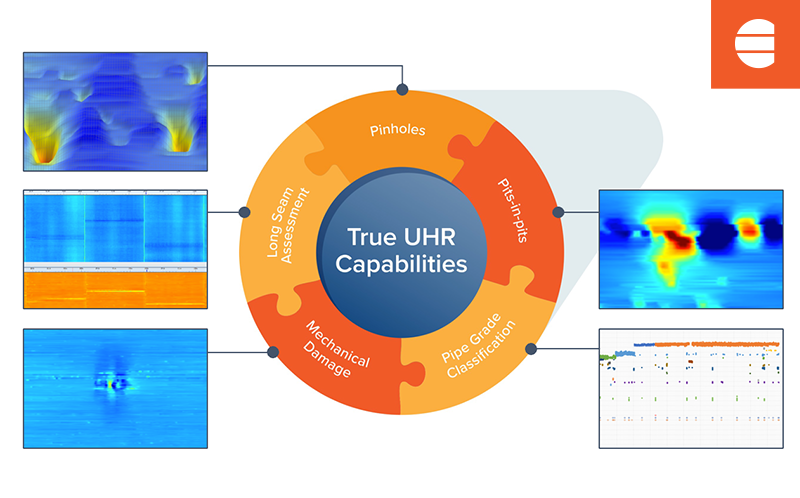

ENTEGRA’s 4X higher data resolution, combined with our unique human based decision making in the data analysis process provides truly complete and informed data. Consequently, ENTEGRA is setting the bar, worldwide, for first-run success, increased throughput, reduced cost, risk mitigation and ROI.

Pits-in-pits. Hard spots. Corrosion on seamless pipe. Puddle welded pipe. When it comes to managing complex corrosion, our ability to identify broader anomaly patterns, more accurately assess metal loss, and apply Ultra-High-Resolution data in combination with the insight and experience of Level III analysts helps our operator partners to address the challenges they face. Efficiently. Successfully. And cost-effectively.

When compared to the impact and cost of unnecessary digs or a pipeline failure, the investment in an ILI run is insignificant. ENTEGRA UHR ILI technology – and our team – help our partners to better meet their moral and regulatory obligation to know their pipeline. That’s the ENTEGRA difference.