Cathodic Protection Current Mapping (CPCM): The ILI CP Solution for Inaccessible Pipelines

ENTEGRA in Action: Read this case study to learn how CPCM benefitted one pipeline operator assess why new corrosion was happening and develop a strategy to address the metal loss Challenge A long-time ENTEGRA® operator partner in California was dealing with a pipeline displaying significant new metal loss. The key challenge: more than six miles …

ENTEGRA in Action: Read this case study to learn how CPCM benefitted one pipeline operator assess why new corrosion was happening and develop a strategy to address the metal loss

Challenge

A long-time ENTEGRA® operator partner in California was dealing with a pipeline displaying significant new metal loss. The key challenge: more than six miles of the 8” crude oil pipeline ran beneath a newly delicate agricultural area. The area was historically known to be dry, irrigation free, and of low rainfall, showing no metal loss over multiple years.

The most recent UHR inspection had revealed new external metal loss that was concentrated in certain areas along the pipeline. It was apparent that corrosion was happening from the MFL run, but what the pipeline operator needed to know was why it was occurring, and how to develop an updated strategy to prevent this new corrosion utilizing cathodic protection — as it appeared the environment had changed. In this scenario, the operator could have been looking at multiple complicating factors indicating CIS or digging would not be the best ways to get the information needed. With the prior history of the land being dry, an external water source would have to be purchased to spray along the line for the CIS survey — an extremely expensive proposition in California. Or, access to the now agricultural area could have been cost prohibitive as well — especially in states with laws blocking easy utility access on private property. Beyond that, sample digging would cause the operator to pay for any loss of agricultural product. These reasons all point to scenarios where an in-line CPCM run becomes natural choice.

Technical Details

ENTEGRA employed an 8” CPCM tool in conjunction with an 8” UHR/MFL combo tool outfitted with both caliper and IMU modules. The CP current plot was correlated and overlaid with two years’ worth of UHR/MFL metal loss indications to form a more complete picture of the pipeline than the operator had been able to achieve previously. They discovered that new irrigation lines had been installed above the pipeline, and they were leaking — the cause of the extensive new metal loss, as well as an indication that this previously dry land needed a new CP strategy.

Outcome

This inspection brought value by providing expanded knowledge regarding the current demand and distribution along this pipeline. Data from field assessments, in concert with CPCM and MFL, helped pinpoint the actual cause of the pipeline’s metal loss as well as its extensive and rapid growth. This helped guide mediation efforts and eliminate costly false positive and false negative calls, especially in a sensitive environmental area that requires the utmost care and cannot afford a potentially catastrophic unplanned release.

Bottom Line

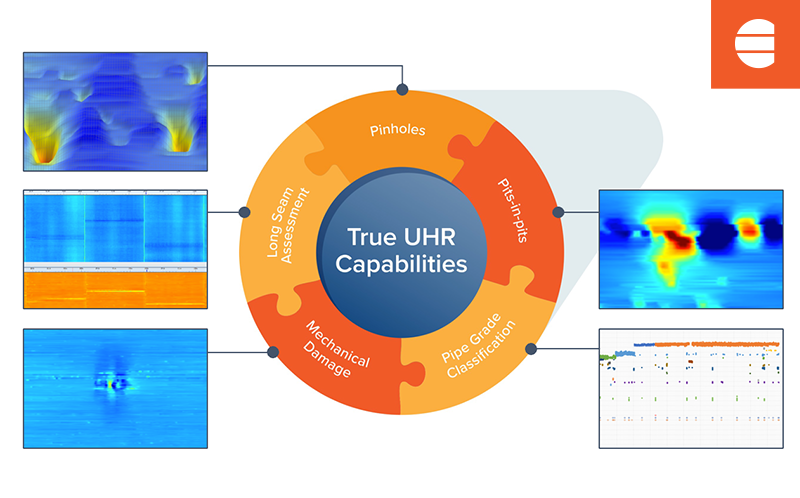

The ENTEGRA CPCM system maps the health of a pipeline’s cathodic protection from inside the pipe, assessing current density and line current, identifying rectifiers and bonds, and detecting shorts — all while the pipeline is in operation. High-quality CPCM data, in conjunction with ultra-high-resolution MFL data, can be leveraged by human-experience based data analysis to provide an unprecedented level of ILI success. MFL identifies where corrosion is happening — CPCM tells you why it’s there.