Corrosion In The Long Seam: A Closer Look.

Metal loss that aligns with a pipe’s long seam is an imminent integrity threat. The ability to locate and identify the seam – regardless of seam type – and then correctly assess metal loss and metal gain anomalies is essential. Differentiating metal loss coincidental, preferential or selective to the seam allows the pipeline Operator to …

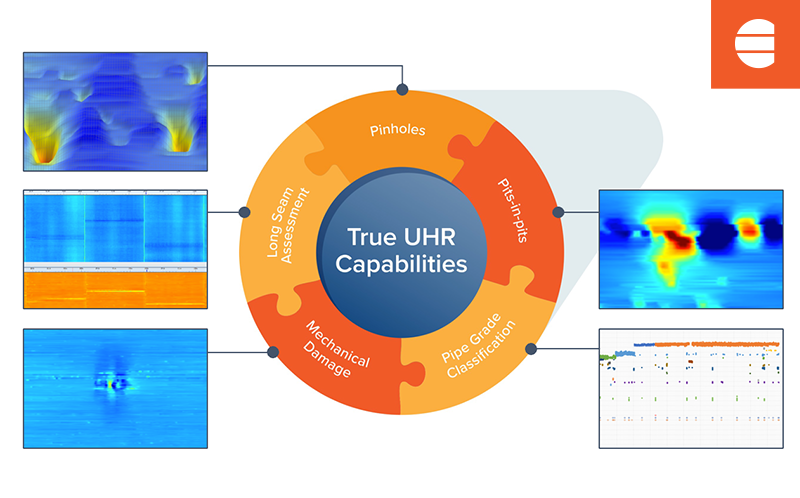

Metal loss that aligns with a pipe’s long seam is an imminent integrity threat. The ability to locate and identify the seam – regardless of seam type – and then correctly assess metal loss and metal gain anomalies is essential. Differentiating metal loss coincidental, preferential or selective to the seam allows the pipeline Operator to more efficiently prioritize their dig program. ENTEGRA’s unique human-based data analysis process can eliminate the numerous false calls due to manufacturing and mill anomalies, when compared to the other seam weld ILI assessment techniques.

Our system of Ultra-High-Resolution ILI tools, backed by experienced, talented Data Analysts, provides more detailed detection, identification and sizing of metal loss. How deep is the corrosion? How long? How wide? What is its orientation to the seam? What is the origin of the metal loss? Before a shovel is put in the ground, a detailed determination of these factors must be made. And ENTEGRA’s UHR system has been demonstrated to do just that.

When it comes to managing corrosion on the long seam, or even complex corrosion such as pits in pits, pinholes, hardspots, or metal loss interactions with puddle welds or seamless pipe, our ability to identify broader anomaly patterns, more accurately assess metal loss, and apply Ultra-High-Resolution data in combination with the insight and experience of Level III analysts helps our operator partners to address the challenges they face. Efficiently. Successfully. And cost effectively.

When compared to the impact and cost of unnecessary digs or an unplanned release, the investment in an ILI run is nearly insignificant. ENTEGRA UHR ILI technology – and our team – help our partners to better meet their moral and regulatory obligation to know their pipeline. That’s the ENTEGRA difference.