Complex Corrosion, Mechanical Damage, Metal Loss and other Pipeline Issues

Learn how ENTEGRA UHR ILI detects these anomalies Differentiating the nuances of complex corrosion in relation to mechanical damage is a common – and potentially frustrating – integrity concern. Physical dents to the pipe. Gouging frequently discovered within those dents. Corrosion coincidental to a plain dent. These are but a few of the conditions that …

Learn how ENTEGRA UHR ILI detects these anomalies

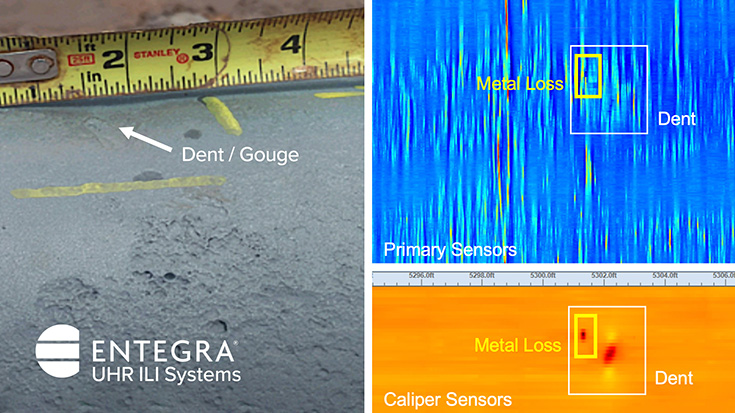

Differentiating the nuances of complex corrosion in relation to mechanical damage is a common – and potentially frustrating – integrity concern. Physical dents to the pipe. Gouging frequently discovered within those dents. Corrosion coincidental to a plain dent. These are but a few of the conditions that can complicate accurate POD, POI and the sizing of any present metal-loss anomalies. Especially those within, or adjacent to, the mechanical damage itself.

Every scenario is different, and such damage may be obstructed in the data when surrounded by metal loss features (and vice versa). That’s why Ultra-High-Resolution MFL, with its higher quality data, is so critical — along with the skill and experience of the data analyst who is assessing the information. Our UHR system allows us to see corrosion interacting with these features and understand their inherent threats for every unique scenario.

What Is Mechanical Damage?

Mechanical damage occurs when a section of pipe is damaged or otherwise deformed by some outside force. Often, this happens during installation of the pipe itself or can be caused by a third party damaging it at some point after construction. While by itself mechanical damage may not always present an integrity threat, it can impede the accurate collection of ILI data.

The ILI system being employed – the process which binds the technology and the analysis – needs to be “tuned” to differentiate between plain dents, gouges, dents with gouges or corrosion that is coincidental to a plain dent, particularly complex corrosion. The goal is to confidently provide an accurate ILI, regardless of the anomalies present.

The Problem with Complex Corrosion

Metal loss that interacts with other areas of corrosion or with common pipeline features such as welds and seams is called “complex corrosion.” While single, easy-to-detect and identify metal loss anomalies don’t normally present a difficult challenge for older technologies, complex corrosion does. As indicated above, this can be especially true when corrosion occurs concurrent with mechanical damage. We’re talking a clear and present obstacle to operators needing a complete picture of their pipelines.

Most ILI methods struggle to assess the nuance between multiple metal loss anomalies acting in concert. In fact, the level of in-depth knowledge needed to accurately assess such complex anomalies was previously thought to be virtually unattainable with ILI. Until now.

The ENTEGRA System

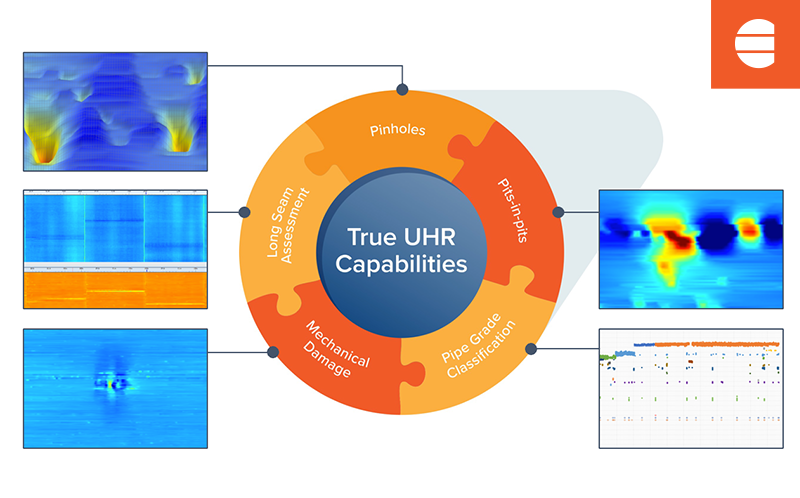

The ENTEGRA UHR ILI system is the combination of UHR MFL tools backed by human-experience based data analysis.

The tools themselves contain a higher number – and concentration – of primary axial sensors than standard MFL tools. They also boast a larger number of secondary sensors like ID/OD. Finally, a dense array of highly sensitive caliper sensors map the surface of the ID wall giving the UHR platform an incredible POD and POI on all aspects of anomalies detectable by MFL technologies.

While the Data Analysis system also employs its own proprietary suite of automation tools, there simply is no substitute for the insight, vision and decision making of a data analyst with years of training and experience. This one-two punch of technology and human-experience based DA is proving itself to be the best approach for detecting, identifying and sizing complex corrosion wherever it presents itself. It also aids in the timely delivery of actionable analysis and reporting.

The Result

The end result? The most detailed and accurate ILI analysis available for the entire pipe, inside and out – and at a first-run success rate in excess of 98%. It is a comprehensive, integrated system for providing today’s pipeline operator with the knowledge and wisdom needed to minimize risk, mitigate threats and better plan for their ongoing remediation programs. This is particularly critical when faced with complex challenges such as corrosion interacting with mechanical pipe damage and the need for fast, accurate reporting.

The ENTEGRA Difference

When compared to the impact of an unplanned release or the cost of unnecessary mitigation, an investment in an ILI run is insignificant.

ENTEGRA’s UHR ILI System — paradigm shifting technology backed by a DA team delivering nuanced data analysis – helps operators to better manage metal loss and the costly challenges posed by complex corrosion. ENTEGRA is setting the bar, worldwide, for first-run success, increased throughput, reduced run costs, risk mitigation and ROI. That’s the ENTEGRA difference.

See for yourself.

Download our whitepaper, “Leveraging Ultra-HighResolution ILI for better POD, POI and sizing of complex corrosion,” for more information on this topic. Just fill out this form to download.