Pipeline Pilferage: Detection Down to the Pinhole

Small Holes Cause Big Problems for Pipeline Operators The Black Market for Black Gold While not a major issue for oil and gas pipeline operators in North America, pilferage is a significant challenge throughout the rest of the world, and cost operators billions of dollars ENTEGRA in-line inspection runs have uncovered pilferage taps ranging from …

Small Holes Cause Big Problems for Pipeline Operators

The Black Market for Black Gold

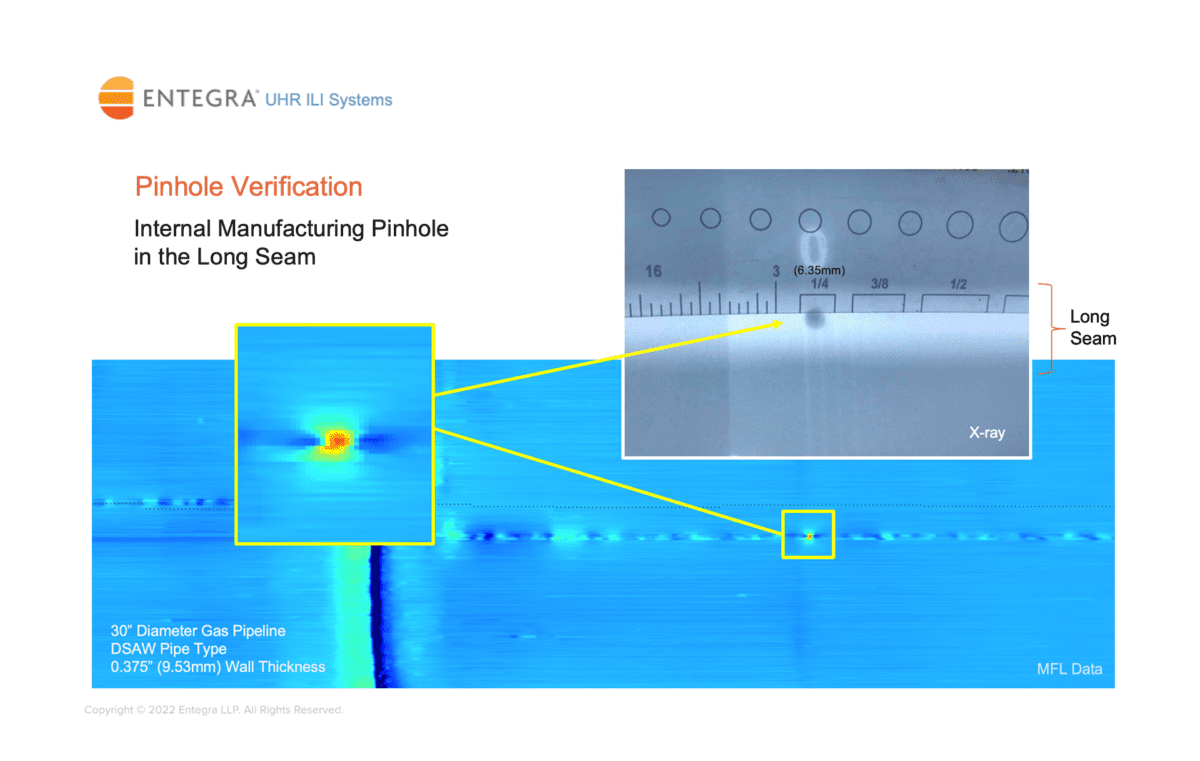

While not a major issue for oil and gas pipeline operators in North America, pilferage is a significant challenge throughout the rest of the world, and cost operators billions of dollars ENTEGRA in-line inspection runs have uncovered pilferage taps ranging from 1” to 1/8” (3mm) in diameter. Even a small illegal tap can lead to leaks or dangerous ruptures, so the financial losses are only part of the problem.

Detecting Pilferage Using Ultra-High-Resolution In-line Inspections

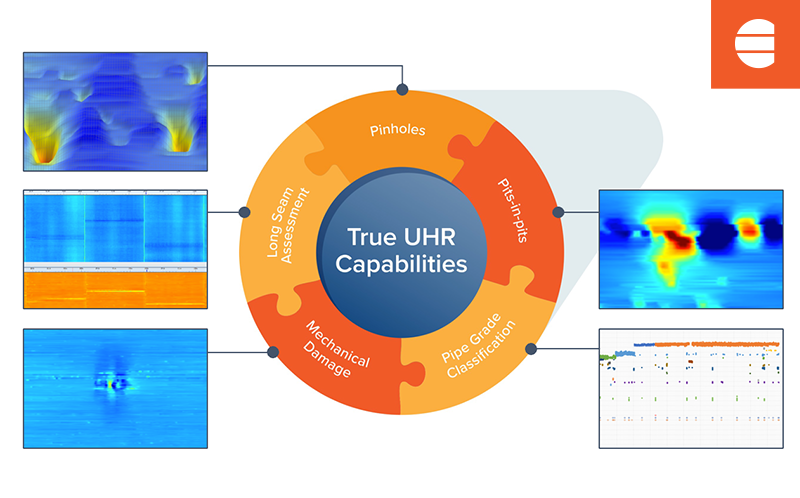

Due to the extremely small size of the access point required for some pilferage setups, many other pipeline inspection technologies cannot find these pinholes. ENTEGRA’s UHR ILI System is fine-tuned for the smallest of anomalies, highlighting problems many others miss — as you can see from our API 1163 qualified pinhole spec. It’s not just the technology that’s important, but our human-experience based data analysis process used to evaluate the information.

ENTEGRA In Action

ENTEGRA tools employ Magnetic Flux Leakage (MFL) technology using an innovative design with a denser array of sensors, improved sensor stability and a higher sampling rate. This adds significant value for pipeline operator partners. The tools are shorter, lighter and more navigable for unparalleled first-run successes. And caliper and ID/OD sensors take data output to a new level for our data analysis teams.

Unfortunately, illegal pilferage operations keep improving their technology just like the rest of us. These can only be combatted by increased awareness, vigilance and integrity inspections.

The ENTEGRA Difference

This technology is backed by human-experience based data analysis, yet another key difference with ENTEGRA’s UHR ILI system. While ENTEGRA has been providing UHR ILI solutions for nearly a decade, our data engineers and analysts have an average of 13 years’ experience in the industry. And that’s not counting the experience and reputation of our team leads, project managers and company principals, many of whom were part of the team that first commercialized MFL technology and the MFL combo tool itself.

ENTEGRA’s UHR ILI System — paradigm shifting ILI technology backed by the insight and experience of our global team — helps operators to see more, know more and do more when it comes to managing pipeline integrity threats. ENTEGRA is setting the bar, worldwide, for first run success, increased throughput, reduced run costs, risk mitigation and ROI. We’re on the case.

Learn more by downloading our paper: How an Integrated UHR MFL System Delivers Better Pipeline Integrity Insights into Pinholes and Pilferage by filling out this form.